The extremely high molecular weight of ultra-high molecular weight polyethylene sheet endows it with excellent performance, and it is a thermoplastic engineering plastic with moder

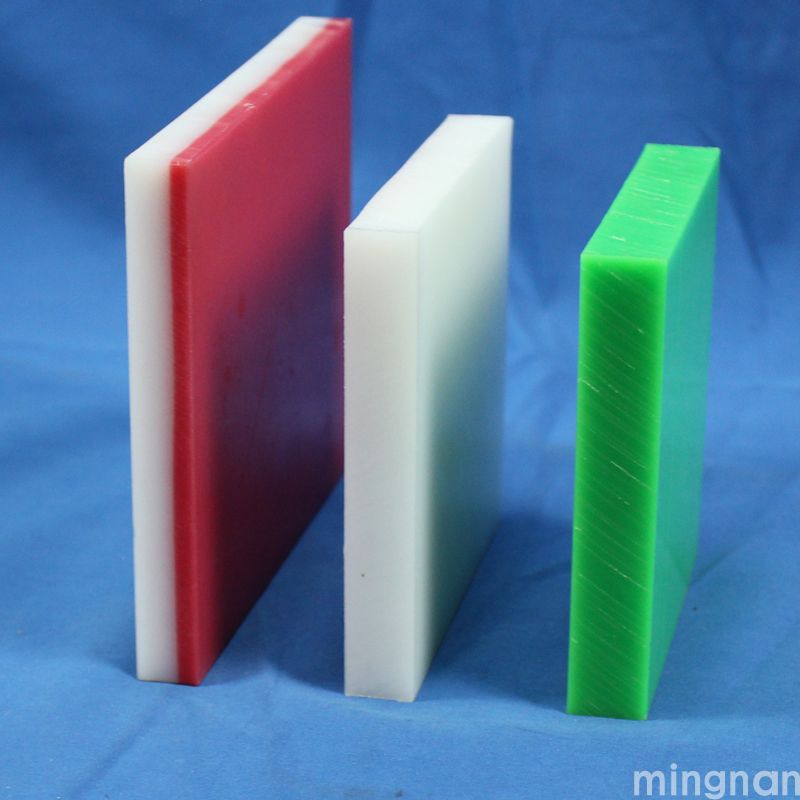

The extremely high molecular weight of ultra-high molecular weight polyethylene sheet endows it with excellent performance, and it is a thermoplastic engineering plastic with moderate price and excellent performance. It almost combines the advantages of various plastics, and has comprehensive properties such as wear resistance, impact resistance, self-lubrication, corrosion resistance, impact energy absorption, low temperature resistance, hygiene and non-toxic, not easy to adhere, not easy to absorb water, and low density that ordinary polyethylene and other engineering plastics cannot compare. In fact, there is currently no single polymer material that combines so many excellent properties.

Ultra high molecular weight ethylene sheets have excellent wear resistance, environmental protection, anti-static, buffering, high wear resistance, moisture resistance, corrosion resistance, easy processing, shock absorption, noise free, economic, non deformation, impact resistance, and self-lubrication, making them very suitable for making various wear-resistant mechanical parts, such as rollers, shaft sleeves, nozzles, and mixing blades, with a wide range of applications.

1. Paper industry: vacuum box panels, dewatering boards, scrapers, sealing strips, paper cutting machine shaft sleeves, etc.

2. Beverage and food machinery: Utilizing wear resistance, impact resistance, non bonding, hygiene, and non-toxic properties, it is used to make workboards, conveyors, gears, etc.

3. Water treatment: sludge scraper, spiral conveyor lining plate, mud pump impeller, pump shaft sleeve, clarification device gear, and sedimentation tank lining plate of the sewage treatment plant.

4. Textile machinery: Utilizing impact resistance, wear resistance, and self-lubrication, such as 36 gears, shuttle machine buffer baffles, bearing liners, etc.

5. Medical devices: human implants, artificial joints, orthopedic instruments and stents, surgical instruments.

6. Automotive manufacturing: Ultra high molecular weight polyethylene products not only reduce the number of parts, but also play a good role in reducing noise. Manufacturers should take advantage of the characteristics of ultra-high molecular weight polyethylene product molding, try to integrate multiple parts as much as possible, reduce the number, and strive to achieve the goal of forming complex parts in one go. The usage of ultra-high molecular weight polyethylene in automobiles is increasing annually.